Tool Room

Tool Room

In the MAF-TEC machinery park, using our huge experience and extensive machine facilities, we implement projects starting from the device concept phase, through processing, to tests or production of details. We also do the implementation of tooling as well as the production of individual parts of machines, device designs, patterns or 3D model.

We provide machining in the following areas:

- turning (conventional, CNC)

- milling (conventional, CNC)

- wire EDM

- plunge EDM

- grinding of rollers and holes

- grinding planes and tools

To carry out orders from our clients, we have many machines and devices in constant production. These are conventional machines such as lathes, milling machines, grinders necessary for unit works and computer-controlled – CNC (CNC milling centers, CNC lathes) that are used in highly complex and increased accuracy works, as well as larger production series.

Thanks to the extensive equipment of the workshop with our own hardening furnaces, presses, etc. We can ensure efficient production.

Tool Room

CNC milling

Haas VF2 SS + 4 axes

Work parameters:

- Working area: x 756 mm

- y: 406 mm

- z: 508 mm

- Spindle 12 thousand rpm

- Electronic divider: Ø 250 mm

CNC milling

Haas VF3 SSYT

- Working area: x 1100 mm y: 660 mm z: 630 mm

- Spindle: 12 thousand. RPM

- Cooling through the spindle

- Set of 3D probes

CNC milling

Haas VF3 SSYT

- Working area: x 1100 mm y: 508 mm z: 630 mm

- Spindle 12 thousand. RPM

- Set of 3D probes

WEDM wire EDM

FANUC C600iA

It includes: PCD diamond cutting module + surface smoothing module

- The maximum dimensions of the workpiece: 1050x820x300 mm

- X, Y axis travel: 600 x 400 mm

- Z axis travel: 310 mm

- Travel along the U, V axis: +/- 100 mm x +/- 100 mm

- Wire diameter: ϕ 0.1mm ~ ϕ 0.3mm

- Maximum wire inclination: +/- 30 degrees / 150 mm

Conventional machine tools

Many types of machines for specific purposes

- Universal / tool lathe - equipped with digital readouts, 2 pcs.

- AVIA tool milling machine - equipped with digital readouts

- RUP grinder for shafts and holes

- Roller grinder

- Tool grinder

- Surface grinder, 2 pcs.

Our projects

Elements of machines and devices

Parts for machines and devices are most often made based on patterns or technical drawings.

For many manufacturing companies, the key to efficient cooperation is a short lead time and high flexibility. Many of these orders require an individual approach and are carried out on conventional machines.

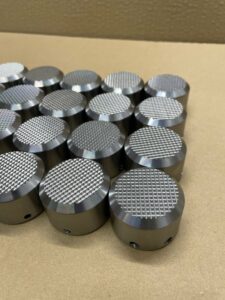

Machining on CNC machines

Thanks to the use of the most modern numerically controlled machine tools, we can carry out orders such as CNC milling, CNC turning. This allows us to obtain high repeatability of the product, high-quality and optimal production costs.

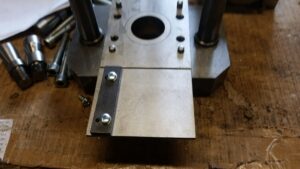

Instruments, forms, tools

MAF-TEC engineers, using their experience, have made numerous projects of various types of molds, dies, assembly devices, welding devices. Some of them we can present here:

By cooperating with us, you can count on full commitment to the project and high quality of all services

We specialize in the manufacture of tools such as punching dies, stamping dies, die-casting molds, rubber molds. We invite you to familiarize yourself with the detailed offer and examples of our implementations.